Borates as additives in brick production: increasing efficiency and quality

The addition of borates to the clay body during the manufacture of bricks or roof tiles offers numerous advantages. Thanks to their fluxing effect, borates can lower the firing temperature in the kiln, which not only saves energy but also increases production capacity. In addition, they improve the strength of the fired product, ensure more intense colouring through the formation of a glaze and make the bricks more resistant to weathering.

Protection against efflorescence and spalling with borates

A common problem with certain types of brick clay is efflorescence and spalling. These are caused by the migration of soluble sulphates to the surface during drying or subsequent exposure to the weather. The result is unwanted white spots and encrustations that impair the appearance of the bricks. The addition of borates inhibits this sulphate migration and effectively prevents the formation of such aesthetic defects.

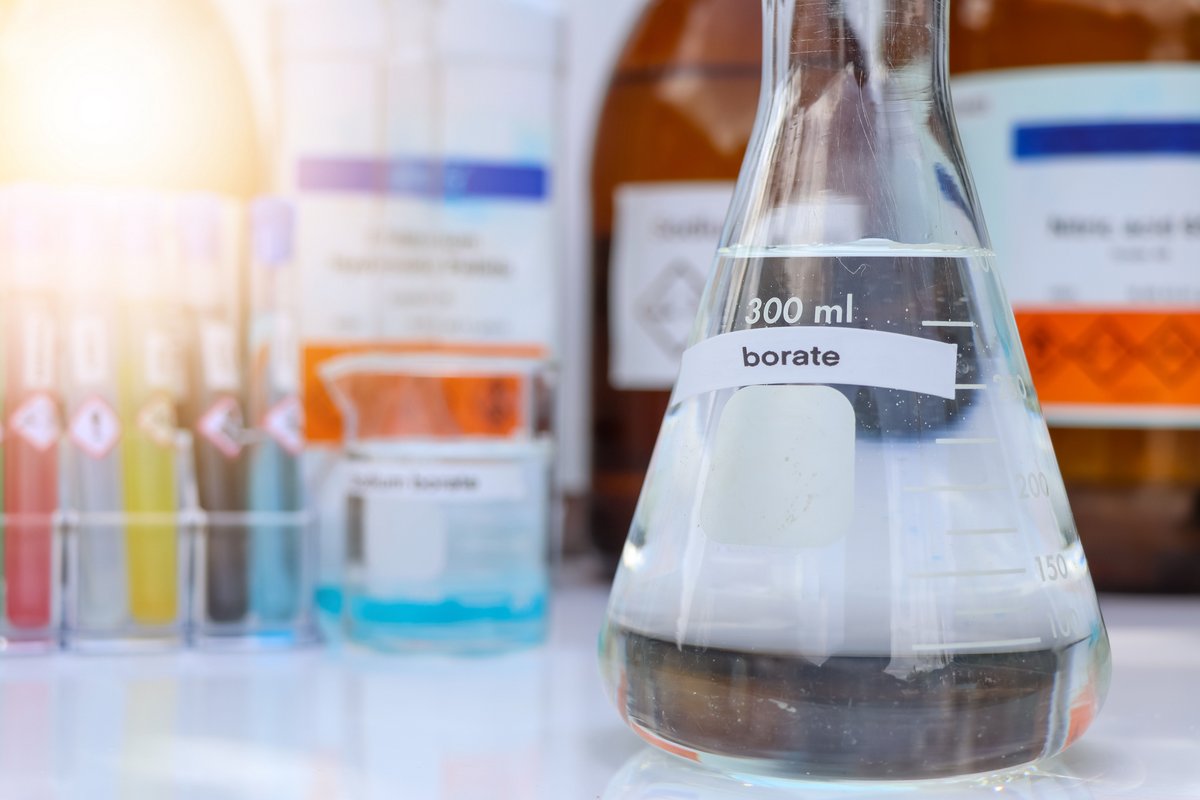

Easy application with aqueous borate suspensions

Aqueous borate suspensions are particularly suitable for practical implementation. These can be easily mixed into the clay body and enable even distribution of the additive. This ensures efficient processing – ideal for modern production processes in contract filling and brick manufacturing.

Do you have any questions or would you like a customised solution for your application?

Talk to us – we look forward to hearing from you!

![[Translate to Englisch:] blauer Tropfen](/fileadmin/_processed_/4/1/csm_tropfen_dunkel_193ae4d1b2.png)